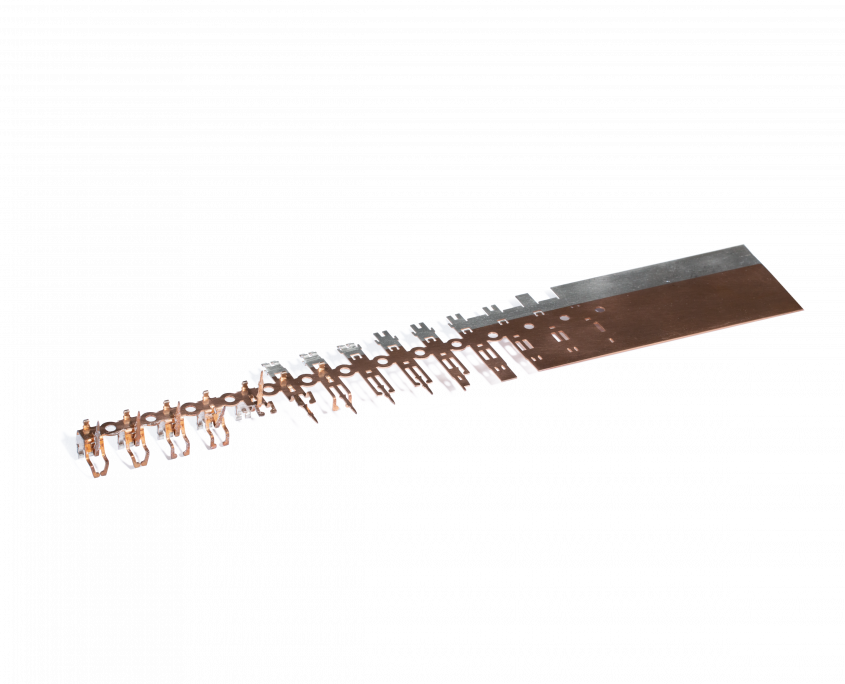

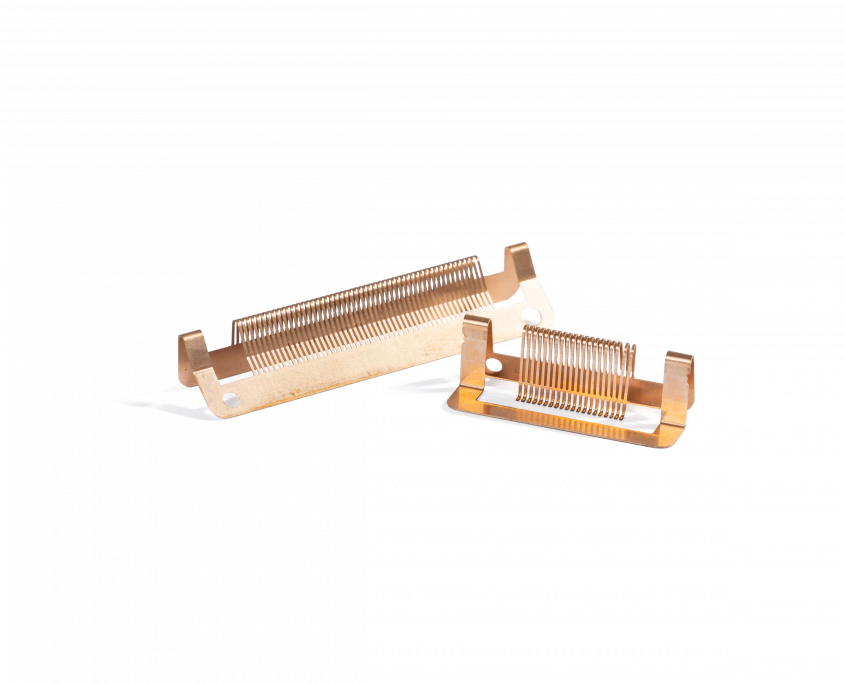

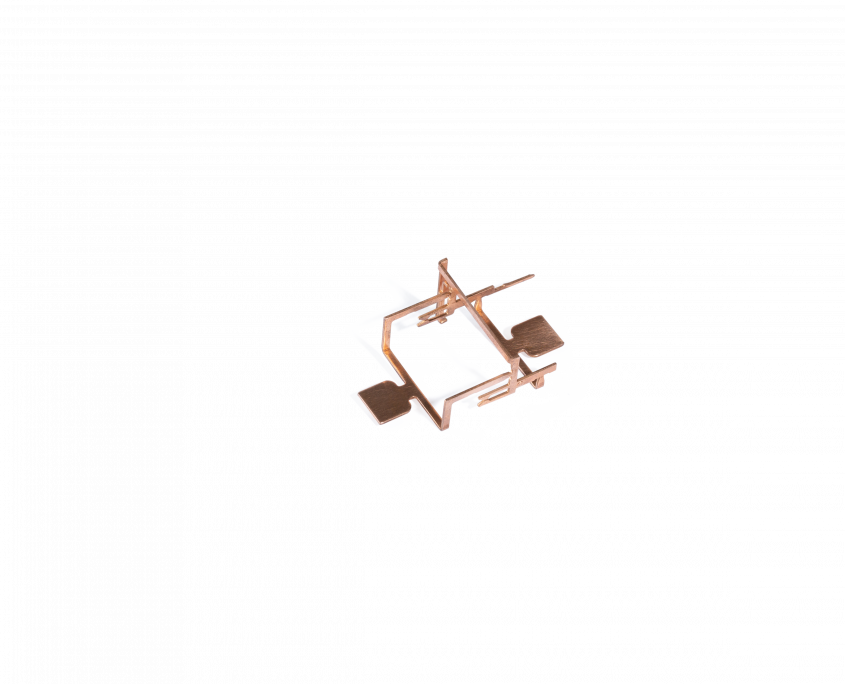

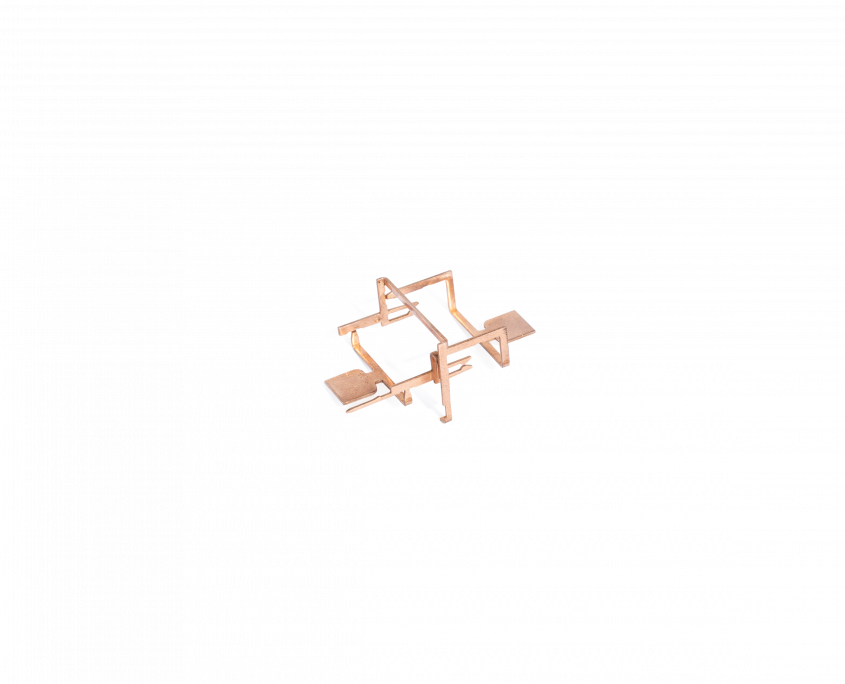

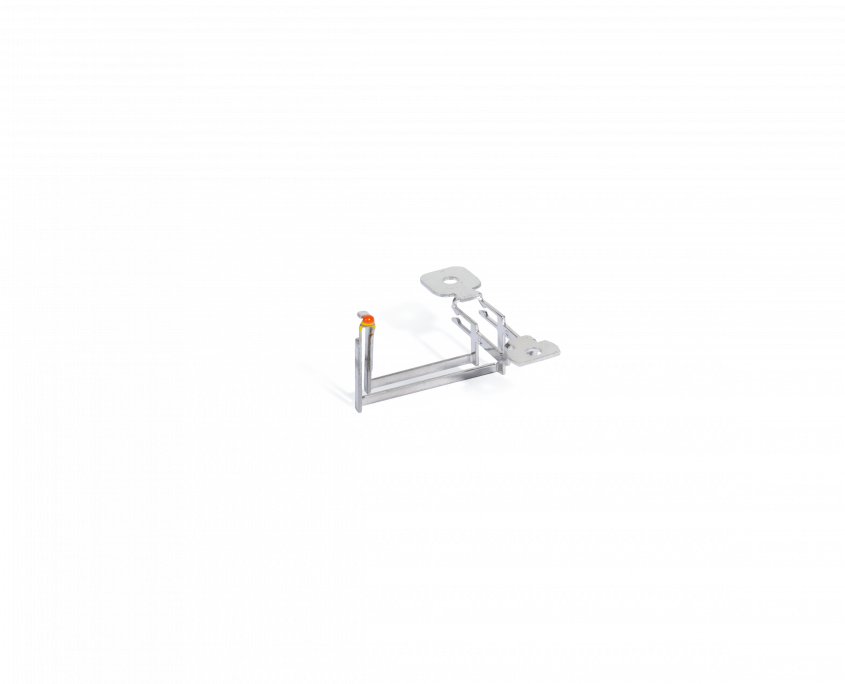

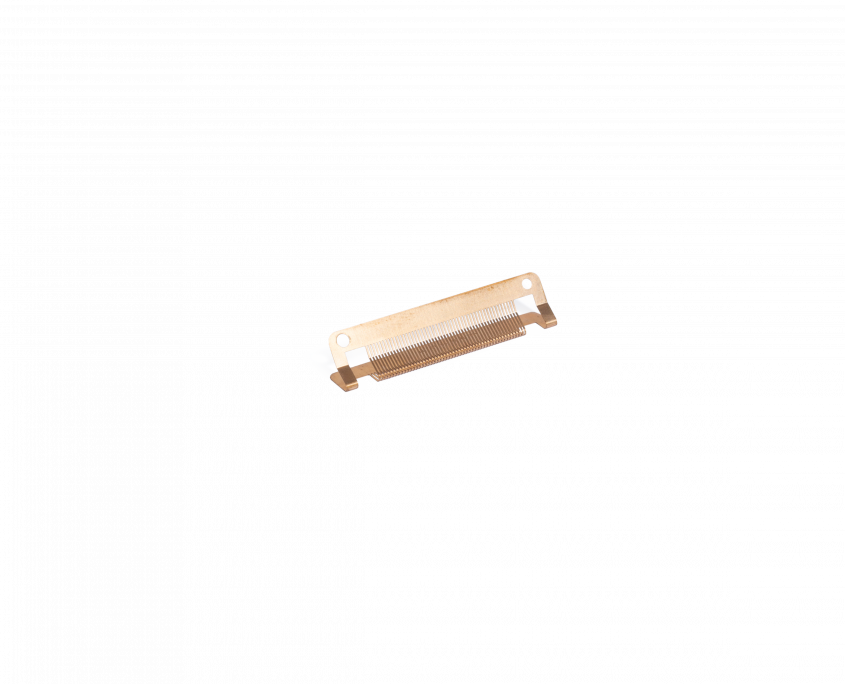

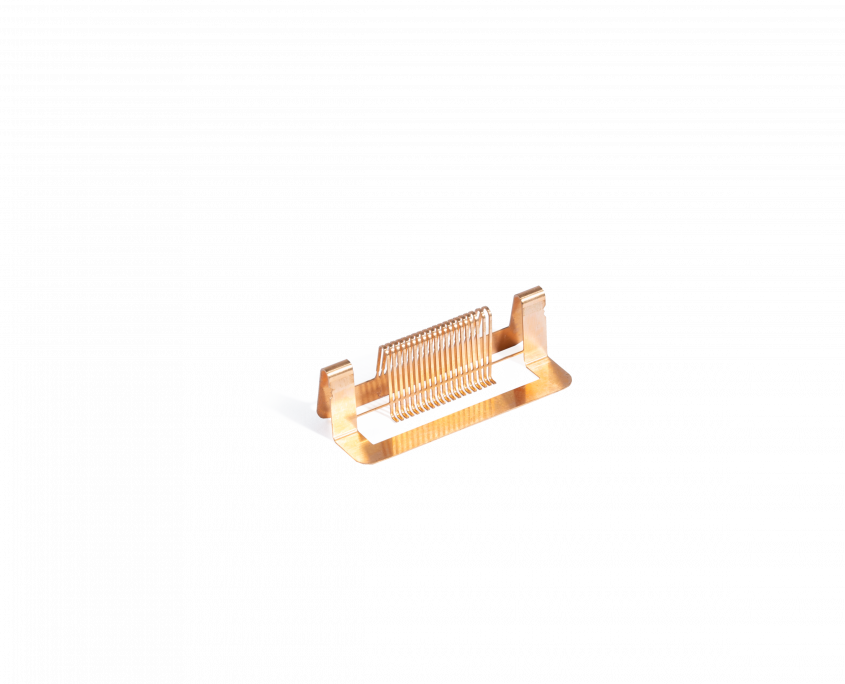

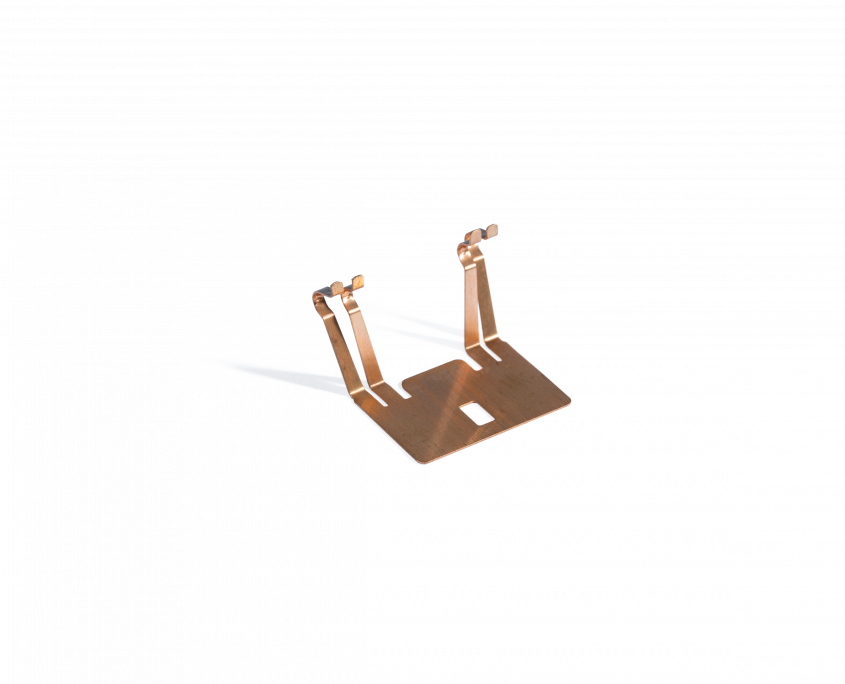

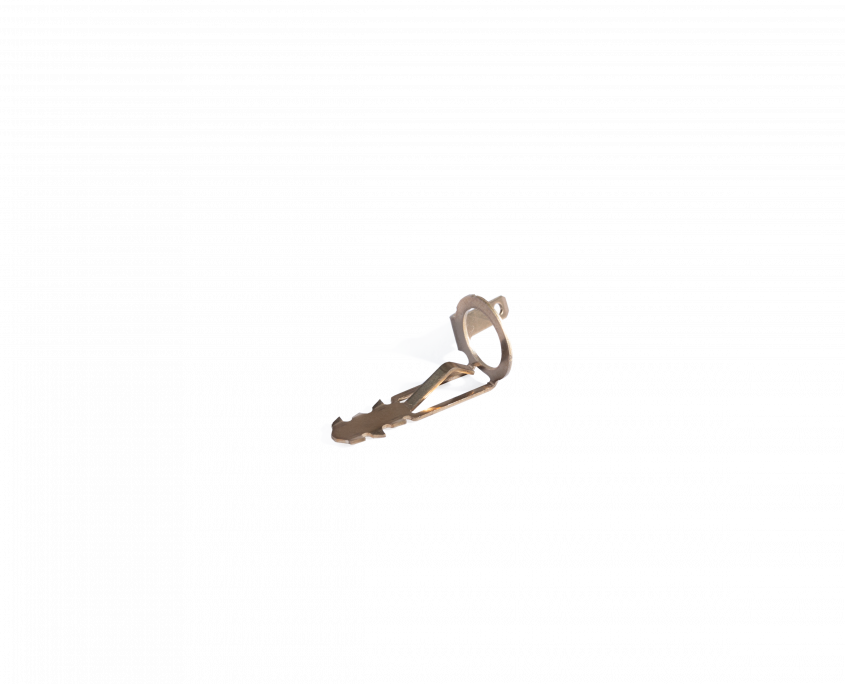

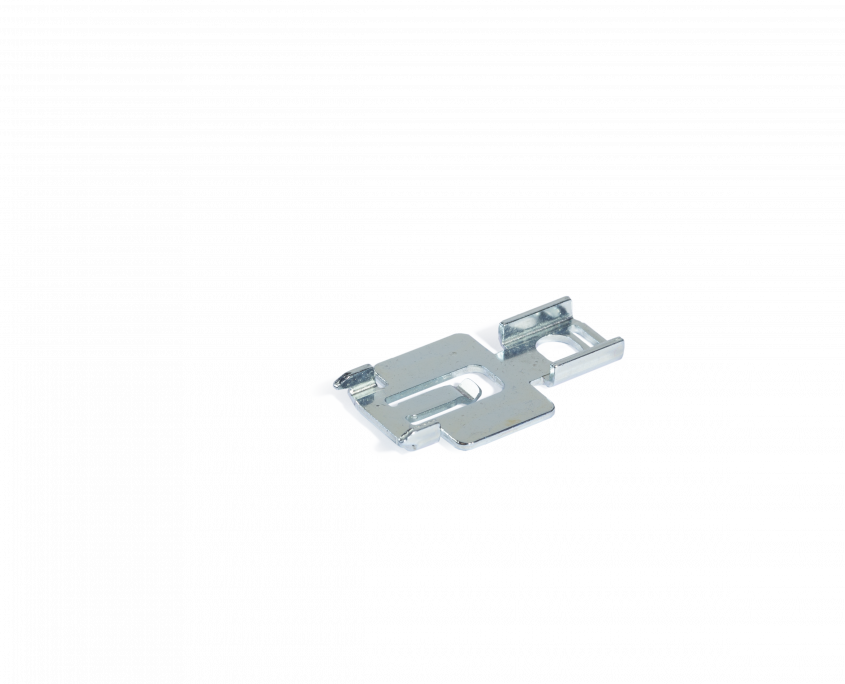

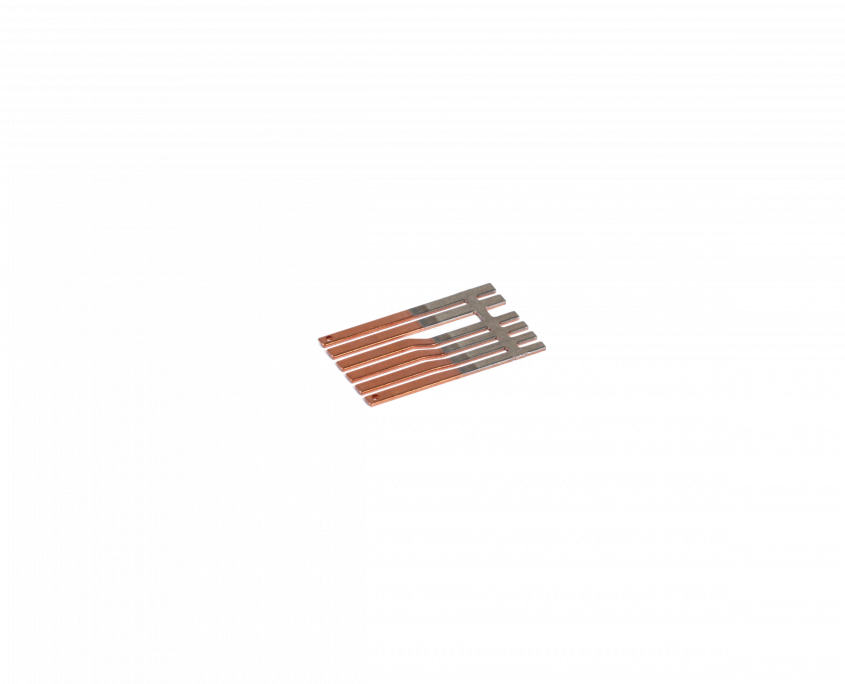

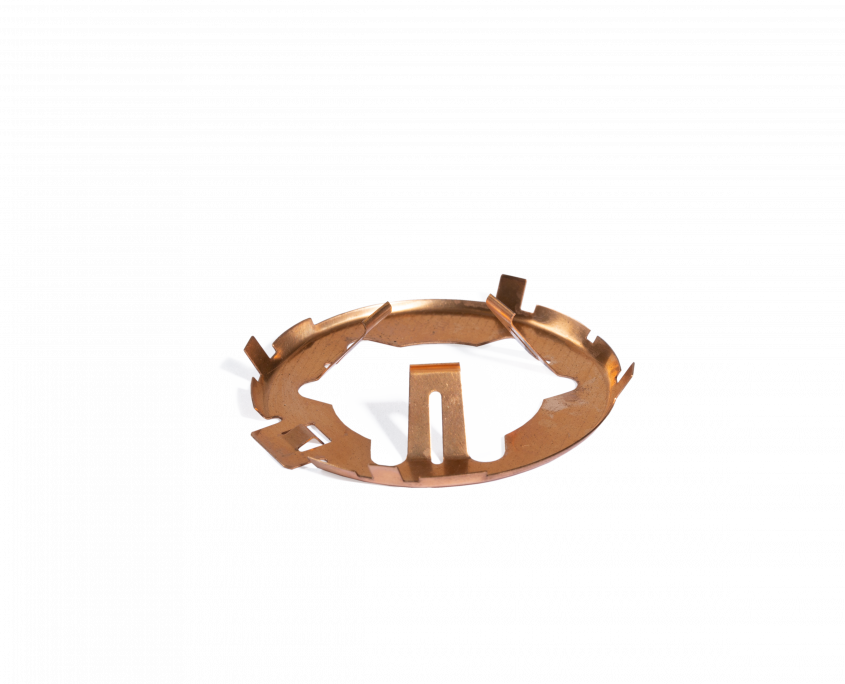

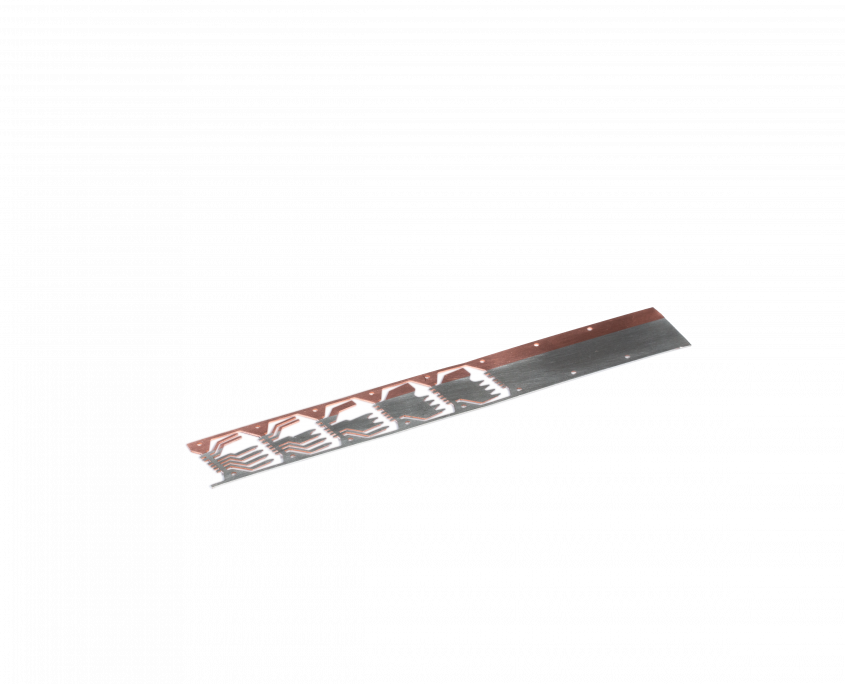

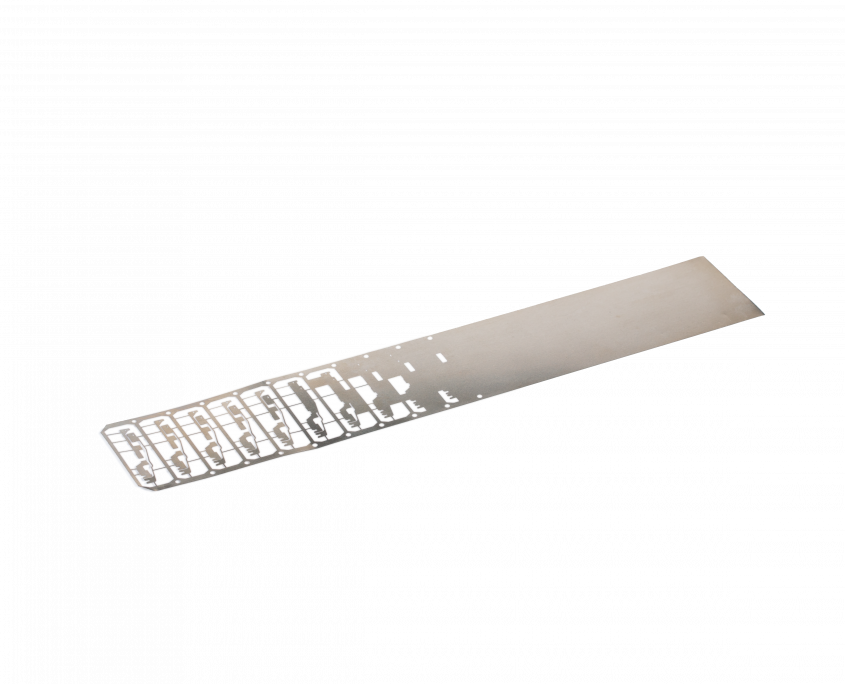

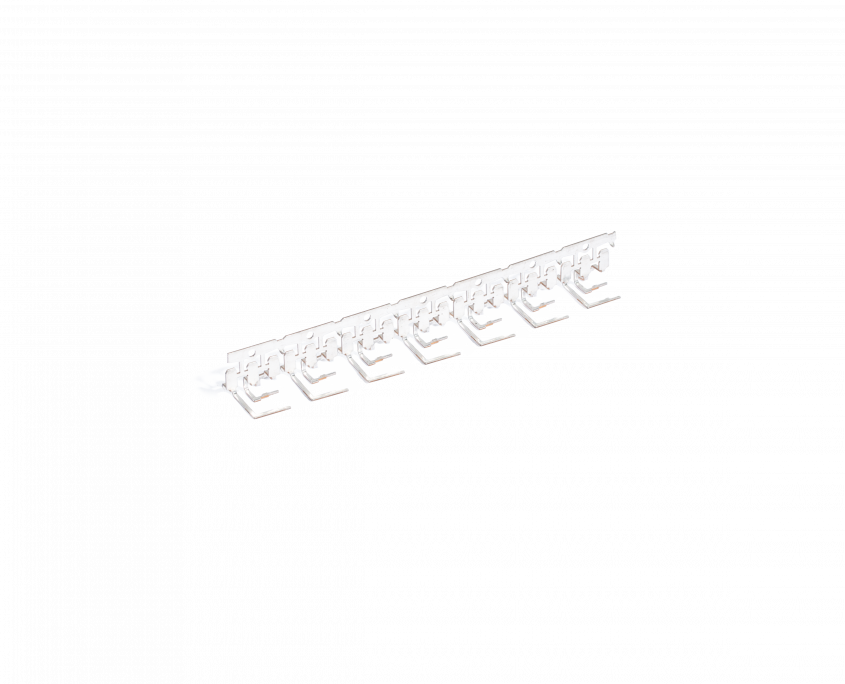

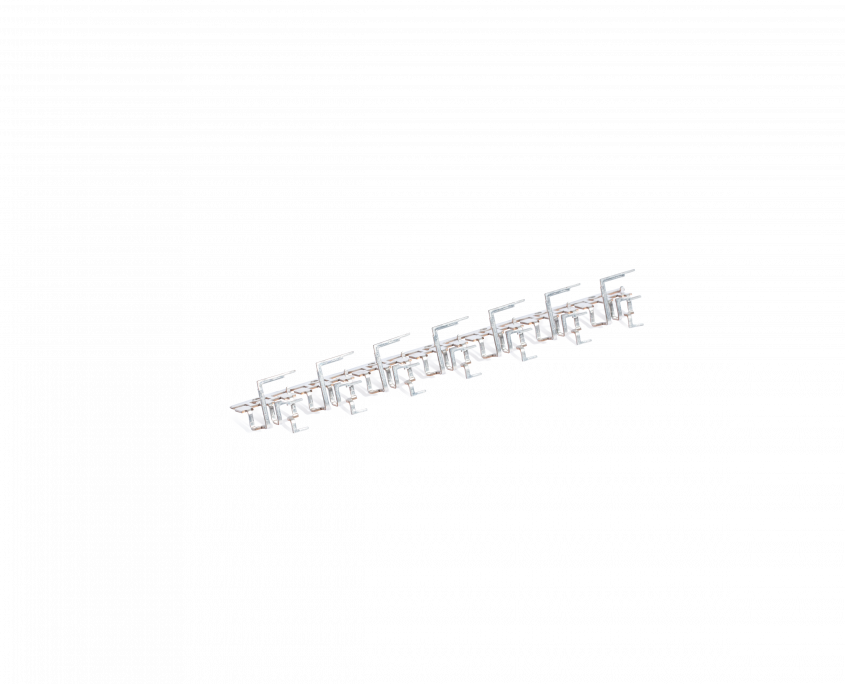

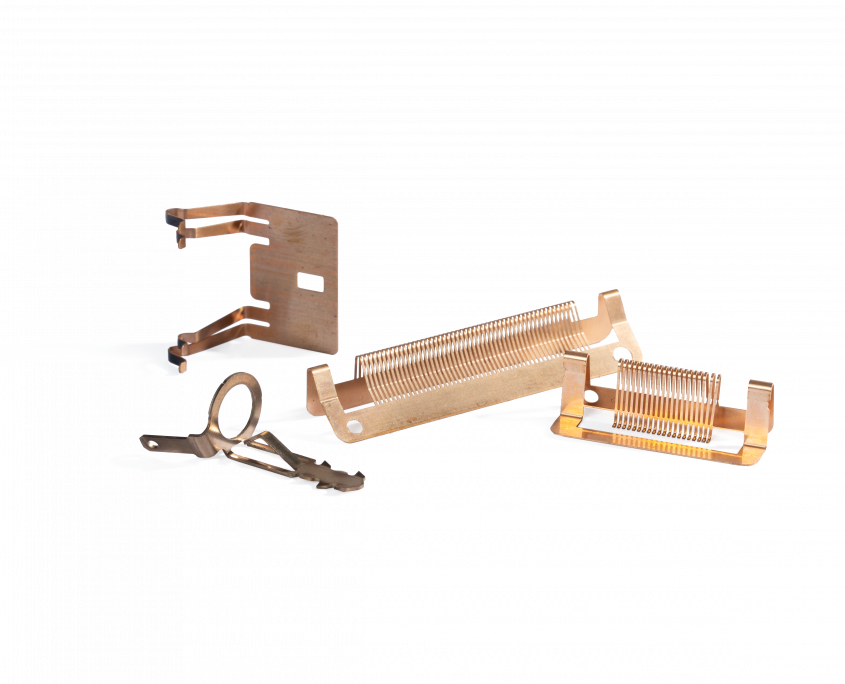

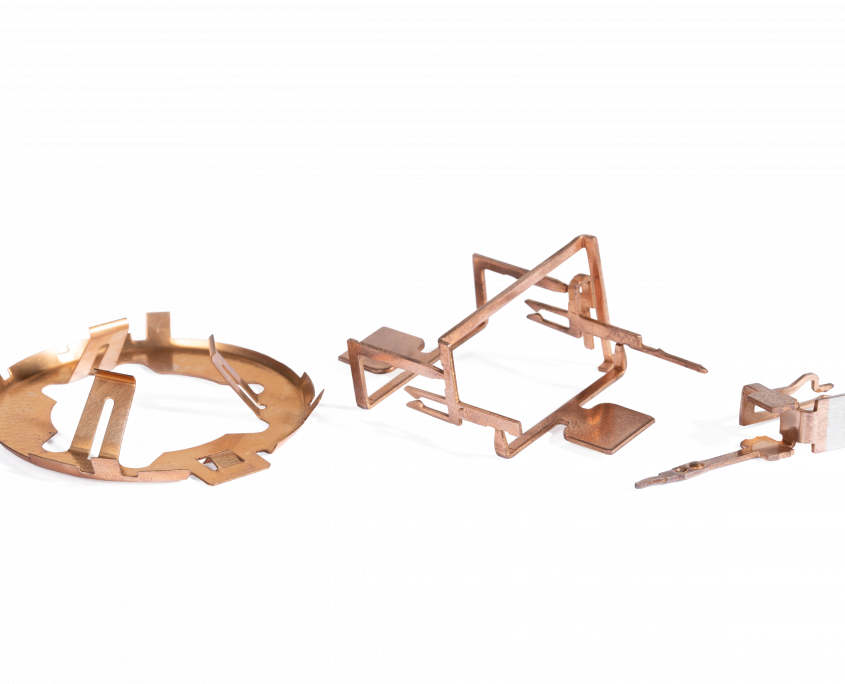

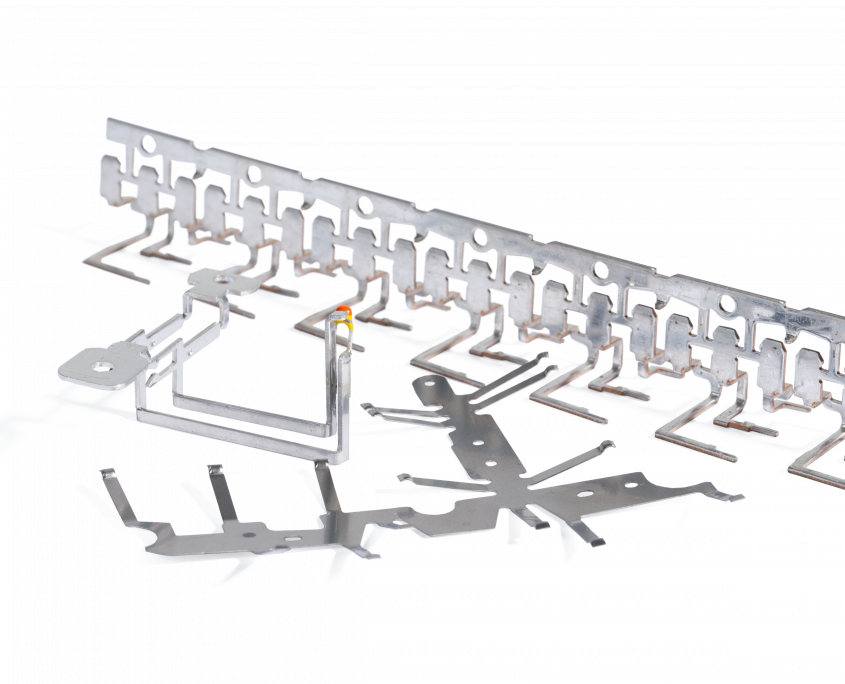

Punching/forming

Für unsere Kunden fertigen wir maßgenaue Präzisionsstanzteile in unterschiedlichsten Geometrien und aus verschiedensten Materialien. Die Einhaltung teilespezifischer Maße wird prozessbegleitend durch den Einsatz modernster Messtechnik begleitet.

Ihre Bauteile können auf folgenden Maschinen gestanzt/bearbeitet werden.

Stanzmaschinen:

- Unsere Stanzmaschinen stehen mit einer Presskraft von 6-63 Tonnen zur Verfügung.

- Auf unseren Stanzen können wir Werkzeuge mit einer Länge von bis zu 800 mm spannen und Blechstärken zwischen 0,1 mm und 2 mm sowie Streifenbreiten bis 150 mm bearbeiten.

Unter anderem stehen folgende Maschinen für Ihre Bauteile zur Verfügung:

- ESSA 35 Tonnen

- Mabu 50 Tonnen

- EBU 63 Tonnen

- Nietmaschinen

- Gewindeschneidmaschine

- Pneumatische-Kniehebelpressen

- Hydraulikpresse Schoen

Konstruktion, Montage, Werkzeug- und Prototypenbau sowie die Wartung und Reparatur im eigenen Haus ermöglichen uns ein flexibles Reagieren auf Kundenwünsche.

Wir fertigen Stanz-, Umform-, Folgeverbundwerkzeuge sowie Prototypen exakt nach Ihren Zeichnungen bzw. Musterteilen.

Unser Werkzeugbau verfügt über einen modernen Maschinenpark.

Für Weiterbearbeitungen wie Wärmebehandlungen oder Beschichtungen, stehen uns langjährige Kooperationspartner zur Seite.

Unser kompletten Leistungen finden Sie hier.