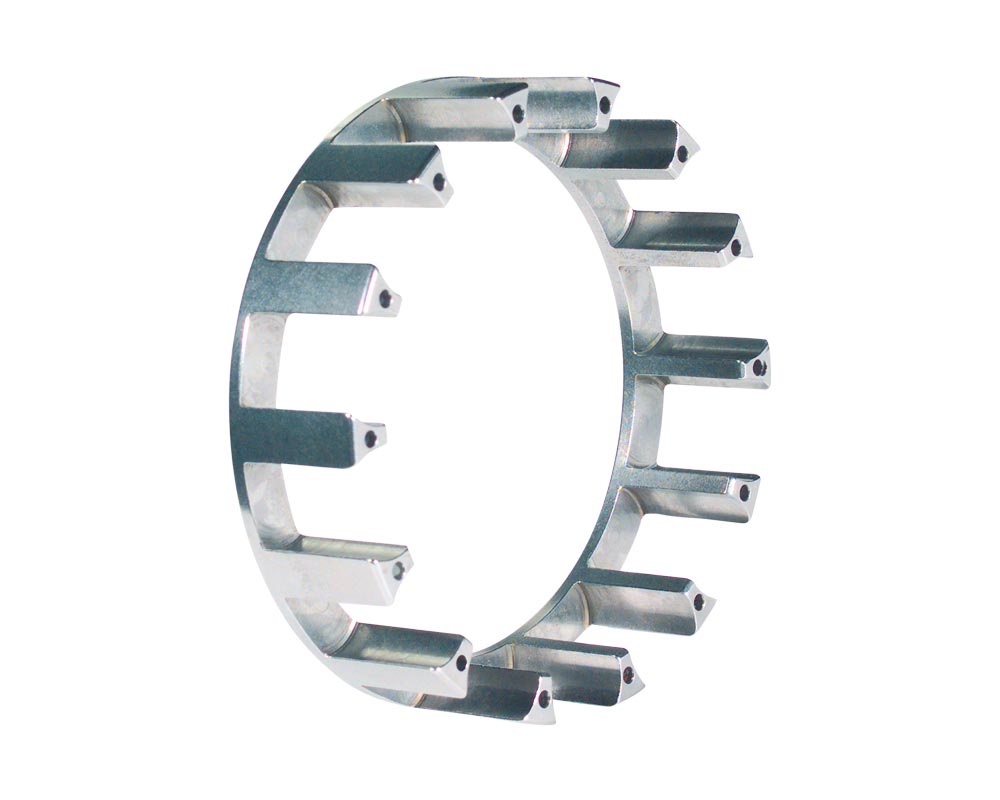

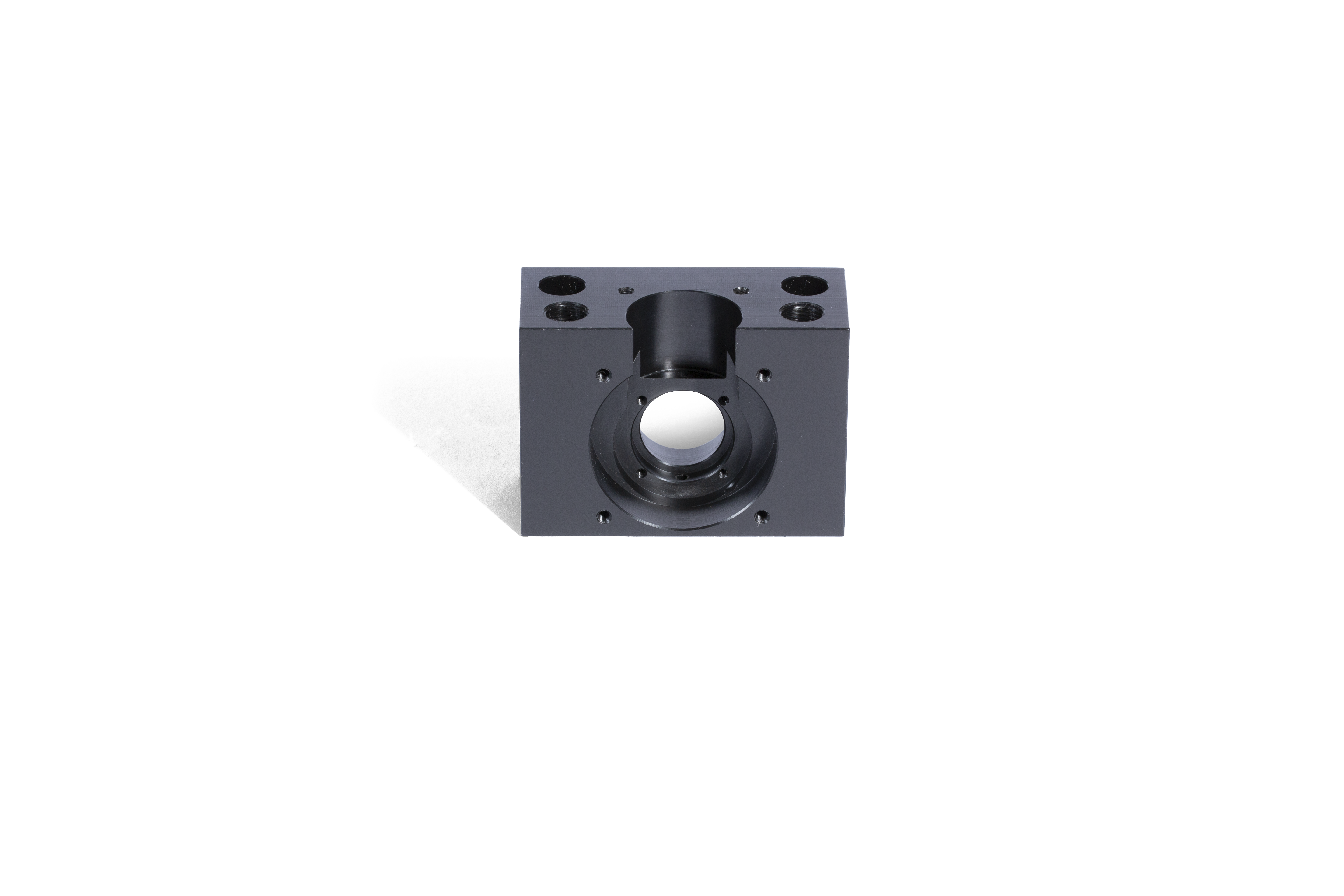

CNC milling

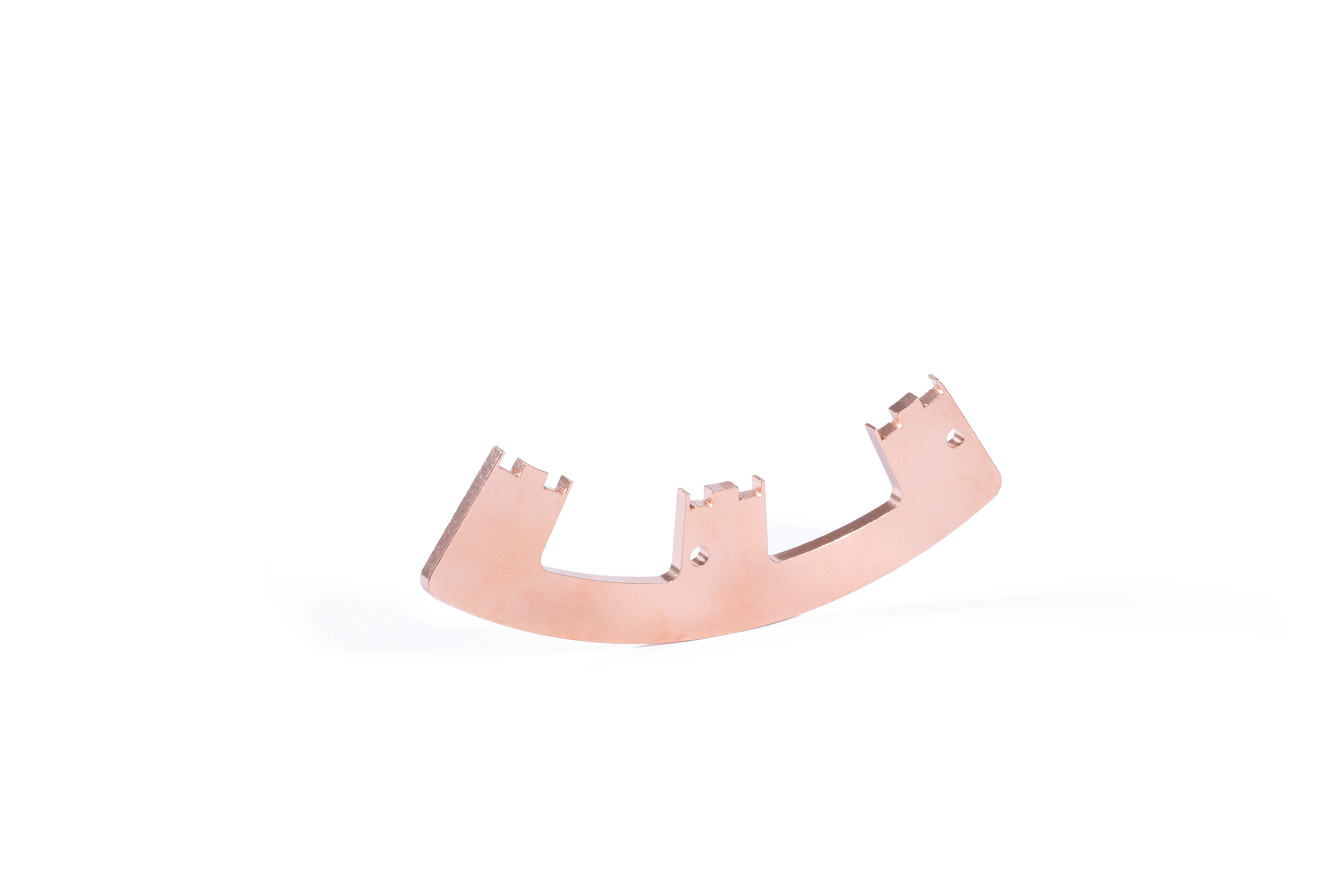

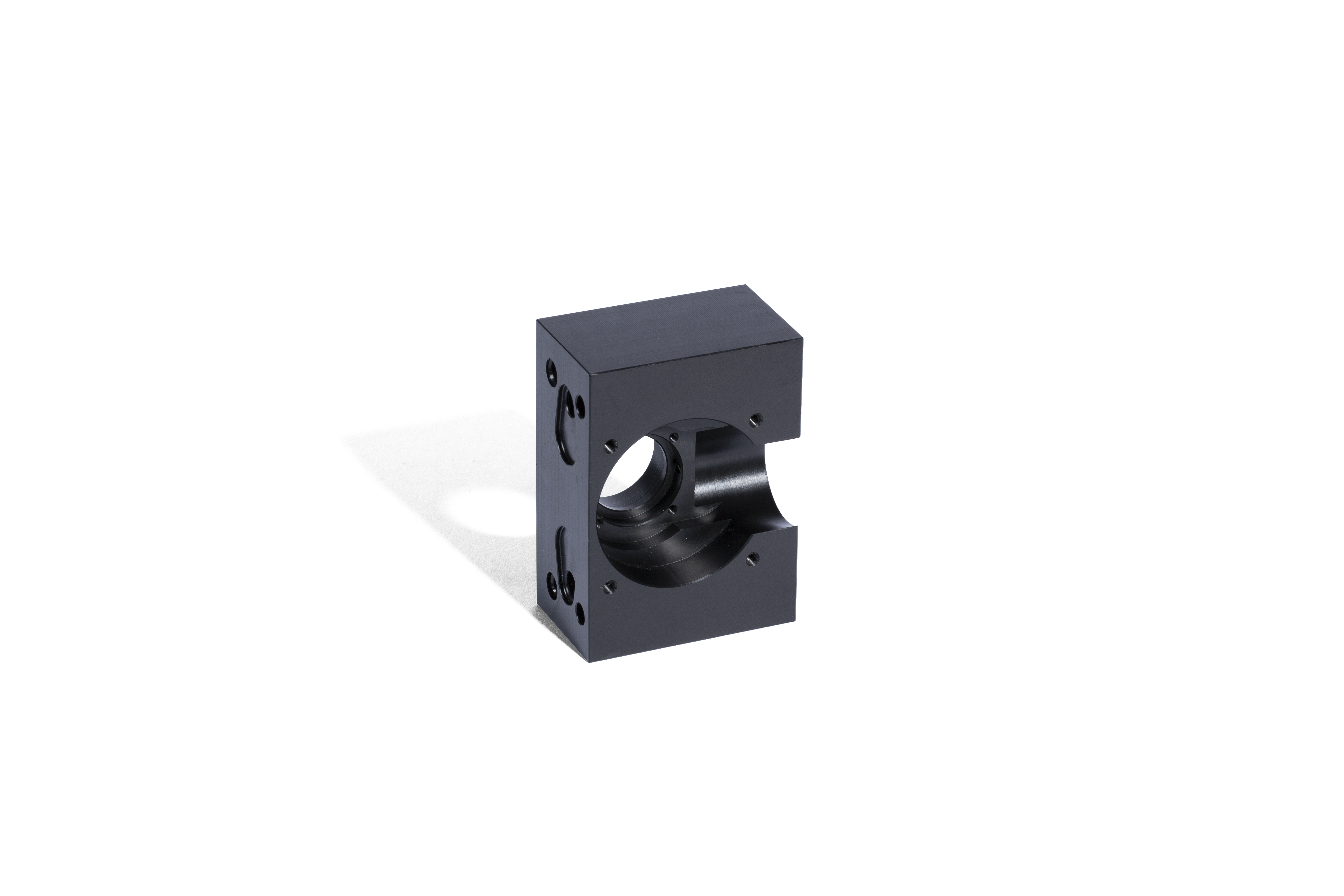

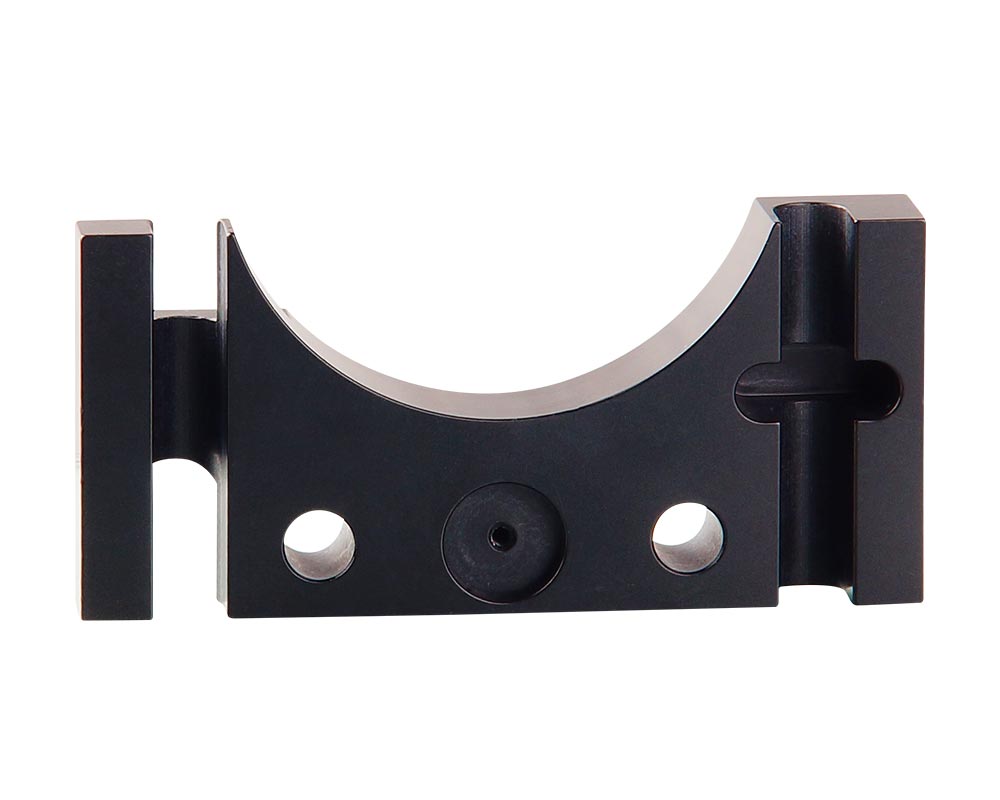

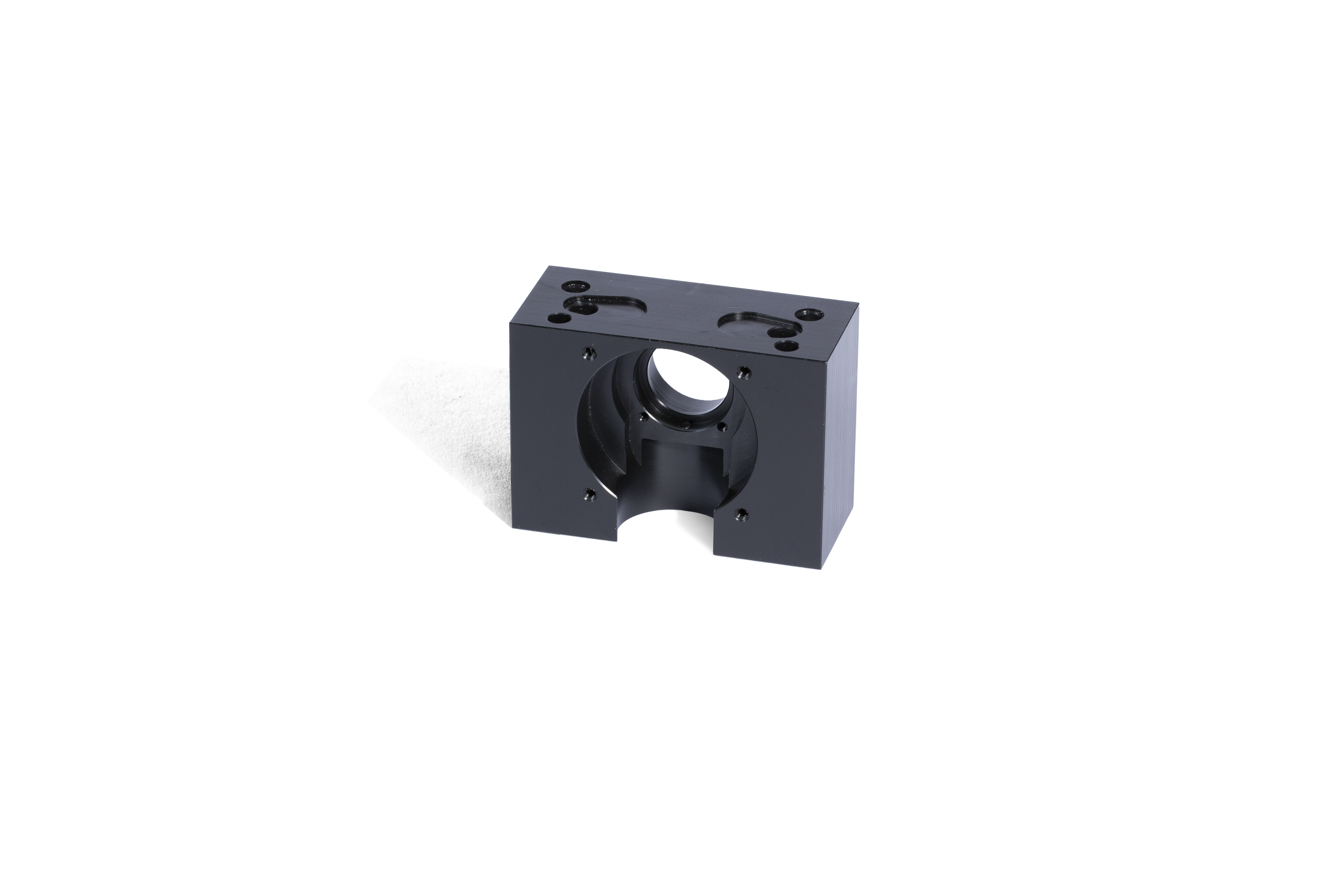

We have been operating in the milling machining and other sectors since 1994 and can look back on many years of experience in the field of professional machining using state-of-the-art CNC milling machines. We manufacture your milled part as a single component or in a small series. To do this, we process stainless steel, aluminium, brass, and titanium, as well as various plastic materials.

- Milled parts up to x = 1500, y = 500 z = 400

- Four-axis processing

- Five-axis processing:

We can process your five-axis parts on our pivoting and shifting tables (up to ø 600mm).

We look forward to receiving your enquiry via our contact form, by e-mail or phone.

General information on CNC milling

Milling is a cutting manufacturing process (machining or chipping). A tool removes chips from workpieces consisting of plastic, metal, and wood. This (chip removing) process is performed on milling machines and machining centres.

A rotating cutting tool removes chips from a workpiece which has previously been clamped into the machine tool table. Certain machines can bring the workpiece into a particularly complex shape because they are able to execute the necessary feed movements along different axes.

These directions include both the x-, y- and z-axes and the corresponding rotation axes. The machine table or milling tool moves along such a vector; the movements per axis are executed one after the other or simultaneously in several directions. These feed movements can be manually controlled via cranks; alternatively, a simple machine can provide for the mechanical control of these movements. For manual control, the operator can read the distance to be travelled from the corresponding scale instrument. For path measurement, however, milling machines equipped with optoelectronic systems are nowadays used almost exclusively in order to ensure highly productive manufacturing conditions.

In the case of both manual and mechanical machine control, tools must always be changed manually. However, the computerised numerical controller is able to perform automatic tool changeovers – as is, for example, the case for CNC milling and for 5-axis milling in particular. These processes run under Computerised Numerical Control (CNC) which is the most efficient milling control method by far. In general, this electronic control and regulation method is suitable for all kinds of machine tools. The CNC machines are closely monitored by special-purpose computers, i.e. the computerised numerical controllers (CNC) which also enable CNC milling and 5-axis milling in particular.

Consequently, the behaviour of a CNC mill can be programmed via a machine controller. For milling machines with up to five axes, this control procedure has already been available for quite some time. The programmed CNC initiates the corresponding feed movements on several axes of its machine tool; these movements take place one after the other or all at the same time.

The distance to be travelled during such a feed movement can be incrementally defined from the current position onwards. Alternatively, the location to be approached next is indicated in an absolute coordinate system.

In extreme cases, the movement required for this purpose can reach speeds of up to two meters per second. This requires a large number of revolutions, i.e. almost 2,000 revolutions per second. However, as a general rule, significantly lower values are applied.

Nevertheless, CNC milling and 5-axis milling in particular are usually much more efficient than manual procedures. Powerful milling machines with simultaneous feed movements along several axes enable agile 3D milling. This demanding milling procedure is able to create complex three-dimensional contours within a short time.

Five-axis milling in particular creates uniquely differentiated 3D contours because the CNC machine can place and move the milling cutter against the workpiece at any angle. Milling machines with up to eight axes are now available in order to enable even more flexible 3D milling. However, conventional CNC milling, and 5-axis milling in particular, still account for a major part of all milling procedures.

We are the competent partner at your side to also support you in the field of CNC turning.