Perfection as standard

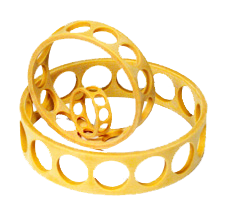

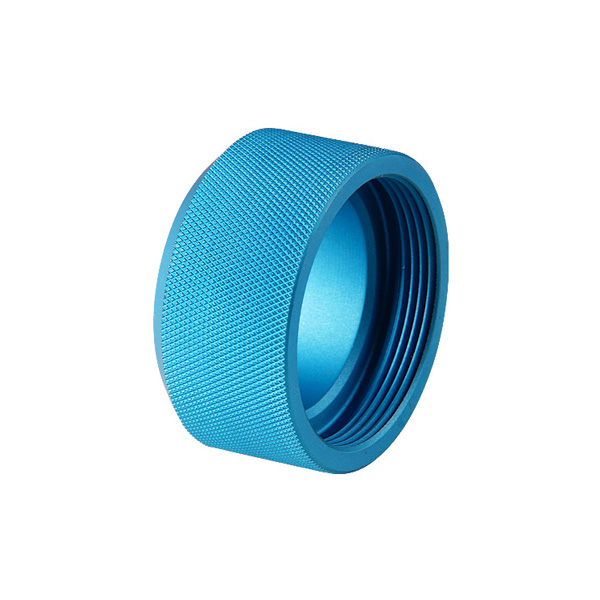

Where extensive knowledge meets long-standing experience, perfection is the logical consequence. Our customers in the metal and plastics processing industry can rely on us for:

- Quality without any compromise

- Flexibility and individuality

Even when it comes to meeting exceptional requirements, you can rely on us to find solutions which provide the basis for high-quality products.

Made from steel, non-ferrous metals, plastic materials such as Torlon, PEEK, PE, POM, PTFE, and Plexiglas, or even composites.

Challenge us! We look forward to your enquiry.